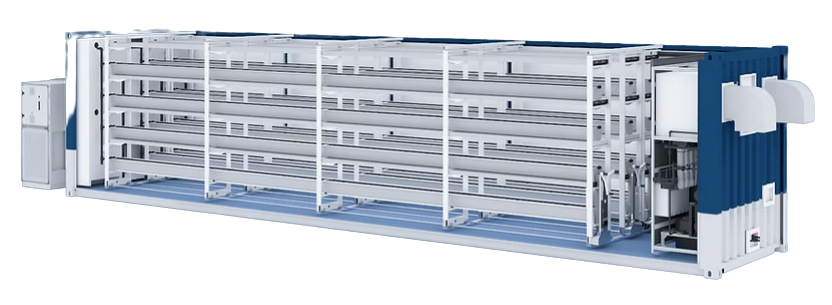

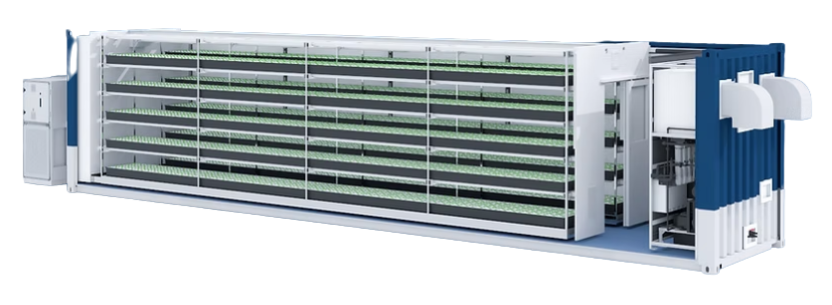

Key Benefits of the BioCube Container Unit

- Low maintenance aeroponics system which can be optimised for any crop.

- Completely transportable, can be located and relocated easily.

- No planning consent usually required.

- Containers are 40ft (12.2m x 2.44m) configurations.

- Can be shipped to almost any destination.

PRECISION NUTRIENT DELIVERY

Aeroponics

GS-AERO Ponics delivers nutrient droplets of 20-60μm directly to roots, optimising growth without water submersion.

Strawberries

Up to 1,224 Planting Cells (per cntr.)

Up to 1,900kg Annum Yield (per cntr.)

70M² Growing Capacity

48 Sections | 4 Tiers | 3 Rows

Leafy Greens

Up to 3,450 Planting Cells (per cntr.)

Up to 13.8 Tonnes Annum Yield

(per cntr.)

70M² Growing Capacity

40 Sections | 5 Tiers | 2 Rows

Microgreens

Up to 230 Planting Trays (per cntr.)

Up to 13.46 Tonnes Annum Yield

(per cntr.)

70M² Growing Capacity

16 Sections | 2 Tiers

Berries Cultivation

Achieve consistent, year-round productivity with an extended 11-month harvest season, and up to 15 yields annually. Our advanced aeroponics system is designed to enhance crop performance, delivering higher yields with larger, faster-growing fruit clusters. This ensures maximum efficiency and profitability for growers.

Vegetables Cultivation

Optimise vegetable production with up to 20 yields per year. Each crop is cultivated to achieve uniform size and weight, reaching up to 200g per unit. The result is produce with vibrant green colour, exceptional freshness, and superior quality, meeting the most demanding market standards for uniformity and excellence.

Aeroponics

Cultivation

System

Customised Lighting

Strategy

Fully Integrated

HVAC

SaaS and

IoT

Support

Space and Energy

Efficiency

Scalable

and

Expandable

Lighting Strategy

Tailored Spectrums & Optimised PPFD Curves For Every Growth Stage.

CROP-SPECIFIC LIGHT RECIPES

Programmable Light Spectrum

Customise PAR (Photosynthetically Active Radiation), PPFD, and spectral blends (380–730nm) for each growth stage.

Our multi-layered lighting ensures uniform distribution across vertical setups, improving yields by up to 25%.

FULL-SPECTUM OPTIMISATION

Light Spectrum Generator

Engineered for CEA (Controlled Environment Agriculture), our lights enhance photosynthesis while cutting energy use by 40%.

Features dimmable LEDs and automated scheduling for seamless transitions between vegetative and flowering phases.

OPERATIONAL SUPPORT

Supporting Container

CF-SPC01:

Designed for Efficient Crop Propagation Support

This container is ideal for small-scale propagation needs or where additional space is required for packaging or cleaning.

– Entrance Area: Includes an air shower, wardrobe, and shoe storage to ensure contamination-free entry.

– Small Propagation Area: Equipped for plant mothering and cloning with self-supporting Fertigation and Irrigation Control (FIC).

– Corridor Area: Features an advanced air purification system to maintain an optimal environment.

– Working Areas: Designed for trimming and drying processes.

CF-SPC02:

Optimised for Large-Scale Propagation

A practical solution for expanded propagation needs or operations requiring additional packaging and cleaning capacity.

– Entrance Area: Equipped with an air shower, wardrobe, and shoe storage for controlled access.

– Large Propagation Area: Supports plant mothering and cloning, complete with self-supporting FIC.

– Corridor Area: Integrated air purification system for maintaining sterile conditions.

– Working Areas: Dedicated to trimming activities.

CF-SPC03:

Perfect for Post-Harvest Operation

Tailored for larger-scale crop management tasks, including drying and storage.

– Entrance Area: Features a purification section with an air shower, wardrobe, and shoe storage to uphold hygiene standards.

– Working Areas: Includes expanded drying zones and ample storage space for post-harvest operations.